Anderson Dahlen’s Distribution Services Expand to Chicagoland

Anderson Dahlen is excited to announce that our distribution segment has expanded to Chicagoland. Partnering with AD Process Equipment, a Gray company, our new stock

Home » Project Peanut Butter Anderson Dahlen Technology Applied To Feeding The World

Anderson Dahlen is partnering with Project Peanut Butter

Anderson Dahlen is partnering with Project Peanut Butter Project Peanut Butter is a non-profit partnership of companies and organizations to reduce the amount of severe malnutrition, which kills more children than any other cause worldwide. The mission has a simple theory to produce food locally from local sources for nutrition and also provide medical support in areas of highest need, currently Saharan Africa and other locations.

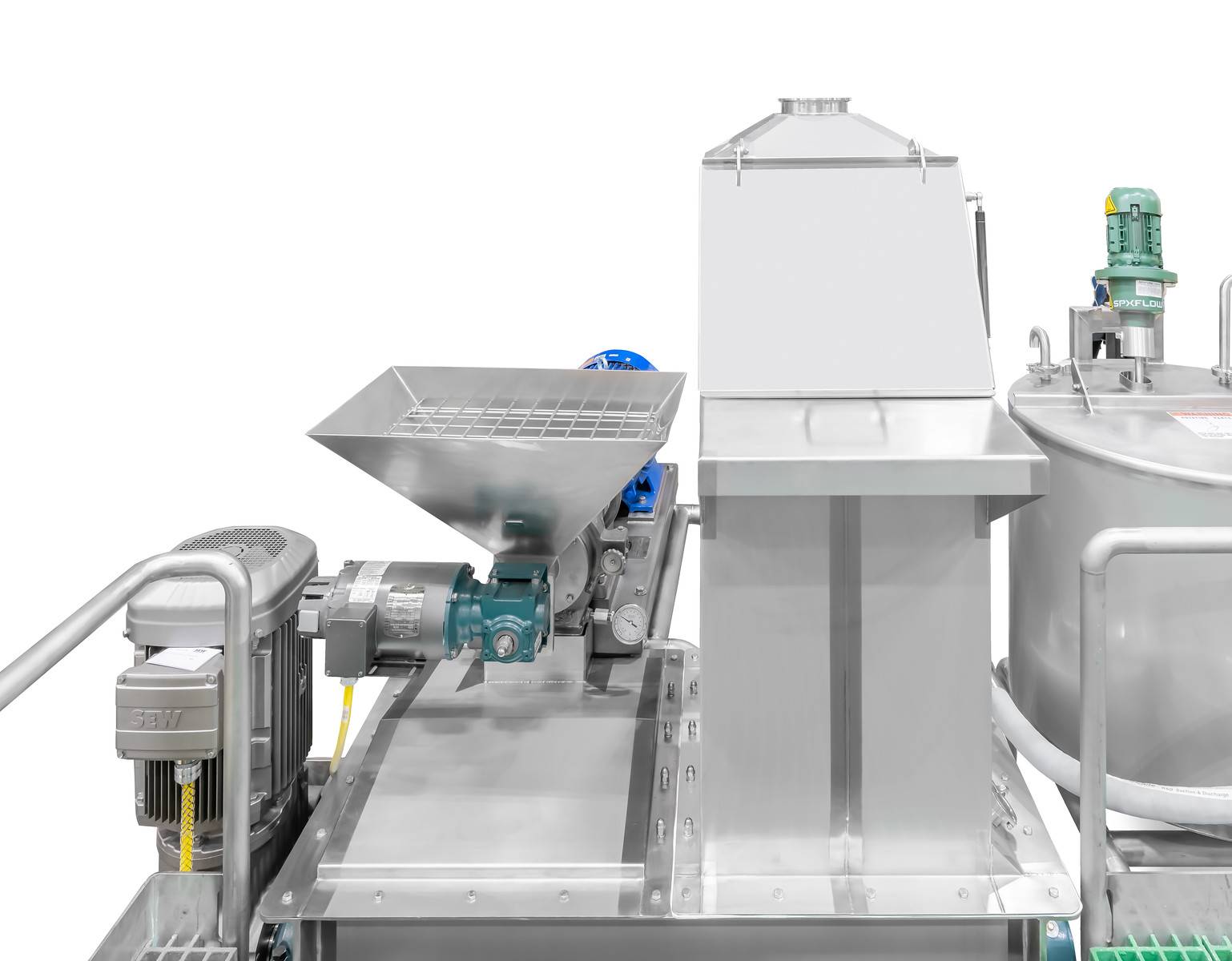

Anderson Dahlen is manufacturing platforms with blenders, small mixers, and grinders; food processing machinery for ready to work delivery into needed areas. These systems are primarily manual to keep them simple, reliable, and make jobs where they are employed. Our engineering and quality craftmanship ensures these platforms will work for a long time with low maintenance which will be critical to the long term success of the projects.

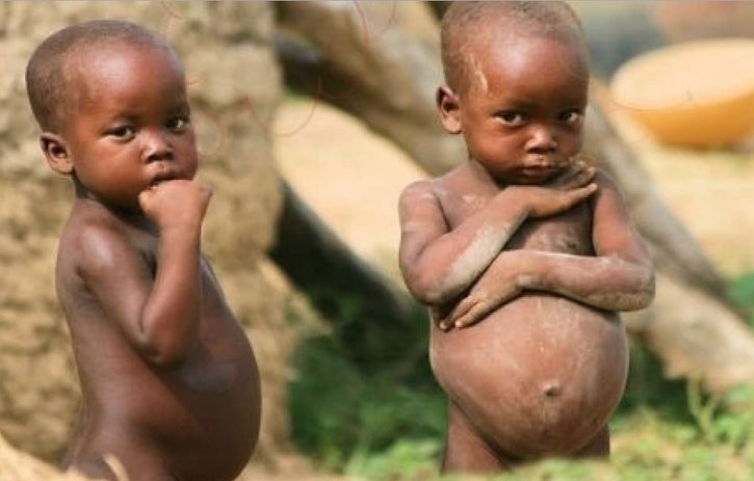

Across the world, Severe Acute Malnutrition affects over 20 million children under 5 years old and causes over 3 million child deaths per year. This is hunger and starvation for nutrients. Even the kids that survive will grow up with major health issues, lower cognitive and physical capabilities. The long-term impact of this preventable disease is huge in many undeveloped countries.

Most of the kids suffering from Severe Acute Malnutrition live in south Asia and sub-

Saharan Africa. These areas suffer from epidemic and ongoing poverty with very restricted access to food with acceptable nutrition. The areas lack the education to know what to do and the manufacturing capability to turn their limited food supply into nutritional products the kids can eat. Few of the countries involved are aggressive at new policies to make a significant change in the epidemic.

So, is it really as simple as feeding kids peanut butter? Not quite. The original Project Peanut Butter formula was developed in the early 2000s by Dr. Manary and Dr. Briend. Their peanut-butter-like formula is called Ready-to-Use Therapeutic Food (RUTF). That doesnt sound all that appetizing, but it is a peanut butter paste with a lot more nutrition. The formula includes powdered milk, vegetable oil, sugar, and vitamins. These are all easy to get to the needed locations.

Local production of the RUTF peanut butter formula is a key to the projects success and where Anderson Dahlen comes in with the food processing equipment to make it all work reliably year after year in local communities with no other source of such nutrition. As many local products as possible are used in the formula production.

The projects are a boom to the local economies and build a self-confident, stronger community with jobs for machinery operators, farmers, nurses and aides, drivers, and others. With local production comes a more steady supply of the nutritious RUTF which makes consistent treatment of malnutrition a reality finally. Compare this to the old methods of feeding third world countries, supplies are shipped in over water; the shipping costs are high, often many of the supplies never make it to the neediest communities, and when they do the customs fees are high and delays are common. Local production is so much better!

Anderson Dahlens place in Project Peanut Butter is growing. We are finishing production on our platform with a cheese blender, small mixer, grinder, and blender. The platform can be shipped as a unit and set up quickly with minimum training. Because Anderson Dahlen has such extensive expertise in manufacturing food processing equipment, we are confident that our system of machinery will work immediately on setup and keep working for many years with minimum maintenance.

We build food equipment for customers around the globe that we are very proud of, but I think this project probably made us feel even a little more satisfied than usual…because of the end-user purpose.” Bill Olsen of Anderson Dahlen

These third world countries have a limited understanding of the cleanliness of food processing machinery and its role in keeping food healthy and non-toxic. In the USA and the rest of the developed world, our food processing cleanliness is kept at an extremely high level. We use CIP and COP systems to constantly clean and sanitize. Our equipment is manufactured for ease of cleaning and to totally avoid food traps that will be problem areas. We are employing these same techniques for the food processing machinery we are making for Project Peanut Butter. These units will be state-of-the-art in terms of ease of cleanliness.

Anderson Dahlen is proud to participate in Project Peanut Butter to help reduce Severe Acute Malnutrition in the over 20 million kids up to age 5 who suffer from this terrible condition. Its our passion to produce the best food processing equipment and this is the perfect opportunity to show off our capabilities while filling a great humanitarian need.

Read more about how we partnered with Project Peanut Butter to manufacture a food processing platform that is ready to ship and stimulates the local economy in addition to providing nutritional rich foods.

Read the full article >>

Learn more about Project Peanut Butter, a nonprofit organization that seeks to advance the treatment of severe malnutrition through ready-to-use therapeutic food (RUTF).

Learn more about Project Peanut Butter >>

Anderson Dahlen is excited to announce that our distribution segment has expanded to Chicagoland. Partnering with AD Process Equipment, a Gray company, our new stock

The dairy industry encompasses an array of products, each with its own processing equipment requirements. Anderson Dahlen’s innovative approach gives us the unique ability to

Discover how MIT and Commonwealth Fusion Systems are advancing fusion energy with high-temperature superconducting magnets, aiming for a sustainable and compact fusion power plant using one of Anderson Dahlen custom vacuum chambers.

Meet Matthew! Matthew Blaha is a Program Manager at Anderson Dahlen. He earned his Bachelor of Science degree from Minnesota State University, Mankato majoring in

Increasing demand for smarter facilities and evolving customer needs are steering equipment manufacturers to incorporate more data into their equipment design and fabrication processes. This

After 45 with Anderson Dahlen, Tom Knoll, president, announced his retirement. With his departure, Jon Nordrum, vice president of operations at Anderson Dahlen for the

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795