Anderson Dahlen and BIX Produce teamed up to custom manufacture a large automated conveyor system. The custom system was designed to improve BIX employee safety, ergonomics, and efficiency. For more than 80 years, BIX Produce has focused on delivering the highest quality produce as well as cheeses, nuts, herbs, spices, and more to customers located in Minnesota, Wisconsin, and North Dakota.

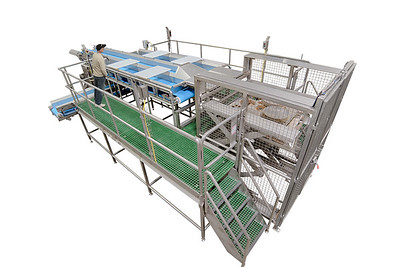

BIX approached Anderson Dahlen to provide design and manufacturing services for a custom design-build solution. A custom, industrial platform with an integrated conveyor and product lifting station was created by Anderson Dahlen’s engineers, CAD designers, and the manufacturing team. The lift was fabricated to raise boxes up and automatically bring them down the conveyor belt to be processed. Engineers designed the system with sanitation in mind and built removable product dividers and quick-release belt tensioners to allow for a thorough washdown and sanitation of product-cutting areas.

BIX reported that the conveyor belt and lift have increased efficiency, decreased waste, and improved ergonomics for the team.