Anderson Dahlen supports pharmaceutical manufacturers by providing solutions to unique problems. As a custom contract manufacturer, we don’t have typical projects. However, in the pharmaceutical space, we are familiar with projects involving single-use bioprocessing technology and other custom stainless steel fabrications. We understand the sensitive nature of confidentiality on these projects, as well as the high need for critical finishes to meet FDA approval requirements.

The vessels and equipment we manufacture are pharmaceutical-grade and often used for blending and batching ingredients in upstream processes. Jacketed tanks, precision components, and equipment for bioreactors are all within our capabilities. We provide full traceability of our raw materials and manufacturing process to ensure compliance with relevant standards, such as ASME. This extensive record-keeping, along with vendor-managed inventory systems, provides superior value to our partners.

Our pharmaceutical equipment manufacturing capabilities include single-use bioreactors, mixers, and fermenters, ranging from 5L to over 5,000L production-ready vessels. With over 1,800 bioprocessing vessels shipped in the last five years, Anderson Dahlen helps biotech and pharmaceutical companies worldwide scale up production faster, meet regulatory targets, and reach the market more quickly. We are a leader in custom pharmaceutical equipment design and fabrication, and we’ll engineer systems to perform consistently with results you can trust for high-purity processing, sterile operation, and reliable long-term service.

From pharmaceutical-grade vessels and extractors to fully integrated turnkey systems, every part of the solution is designed for FDA compliance, traceability, and cleanroom-ready finishes. Whether your company is manufacturing bioprocessing vessels, sanitary stainless steel platforms, or other critical components, we ensure batch consistency, thermal accuracy, and peace of mind at every step of the process.

Every pharmaceutical project presents its own unique challenges, and we possess the experience and capabilities to effectively address them. We design and build everything from jacketed bioreactors, mixing equipment, and custom fermenters to help streamline your process, reduce the risk of contamination, and cut processing time. The equipment we fabricate is also engineered for cleanability, sterile processing, and consistent batch quality, which makes it ideal for both clinical-scale and production-scale pharmaceutical manufacturing.

Every vessel, system, and fabrication is manufactured to Anderson Dahlen’s FDA-compliant standards, like #8 and 8–20 RA surface finishes, which are critical for pharmaceutical CIP (Clean-in-Place) and SIP (Steam-in-Place) systems. We also build compliance into your project from the start by including documented quality plans, weld mapping, and final inspection reporting to meet the most demanding pharmaceutical validation standards.

Your new products are your competitive advantages, which is why we protect your intellectual property with strict confidentiality agreements, revision-controlled documentation, and secure environments for both engineering and manufacturing.

We design and build custom pharmaceutical-grade vessels for processing, like jacketed tanks and specialized components for bioreactors. These solutions help manufacturers control the consistency of their products, including active pharmaceutical ingredients and vaccines, from batch to batch.

Certified to ASME Section VIII, Division 1 and PED-compliant for European use, our pressure vessels are engineered for operating pressures from 15 to 2,500 psi and available with dimple, half-pipe, or conventional jacketing for precise thermal control. Dimple and half-pipe jacketing are ideal for biologics and other cell cultures that require tight thermal profiles and sensitive APIs.

Our vessels are made from pharmaceutical-grade stainless steel and other specialty alloys to ensure maximum corrosion resistance, cleanability, and long service life. They are also designed for USP Class VI compliance, allowing them to withstand aggressive cleaning cycles without degradation.

We have earned and maintained certifications from independent organizations to help you trust our quality.

We subject every project to advanced inspection, including XRF PMI, ultrasonic flaw detection, dye penetrant, and magnetic particle testing to uncover defects. Our team of AWS Certified Weld Inspectors is qualified to inspect every weld and joint on each piece of equipment we manufacture.

We offer full traceability starting from the mill of origin for all materials. We can supply MTRs, weld maps, inspection reports, and certificates of conformance for every project to provide complete confidence in our work. We endeavor to meet whatever documentation standards your project requires.

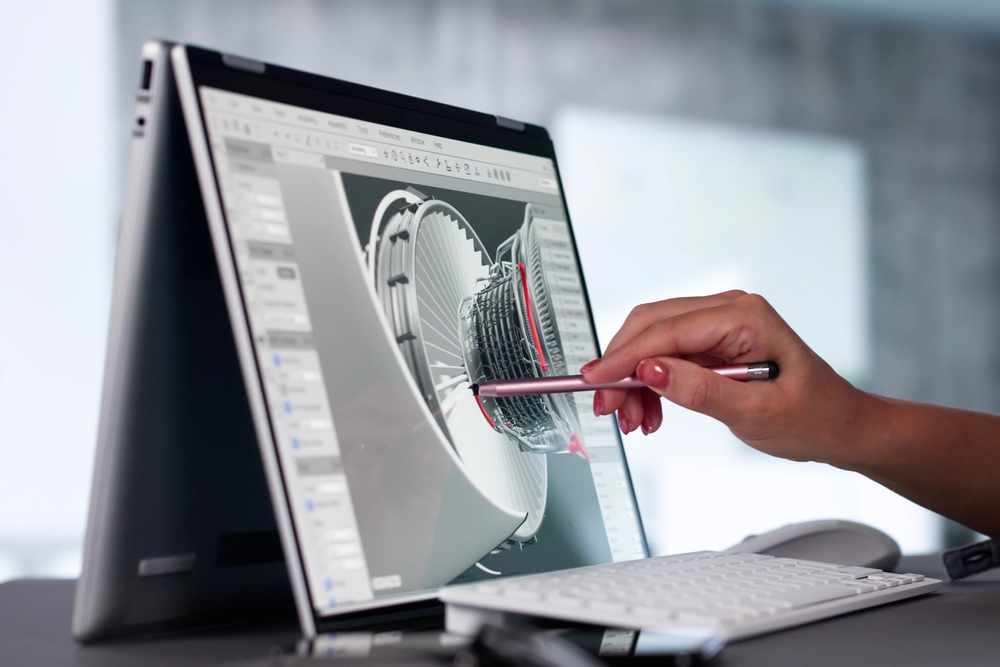

We can build your solution from existing drawings, but our engineering team also uses advanced CAD modeling tools, secure PDM vaulting, and over 200 certified welding procedures to develop precision pharmaceutical systems. Our team members include project managers, engineers, and skilled production personnel who can all be on-site or on-call when needed.

Anderson Dahlen boasts over 75 years of custom fabrication experience, 363,000 sq. ft. of manufacturing space, and the resources of our parent company, Gray, behind us. As your trusted partner in bioprocessing technology and sanitary processing equipment for life sciences manufacturers, our systems are engineered for compliance, reliable performance, and scalability to support the innovation of the next generation of pharmaceutical products.

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.