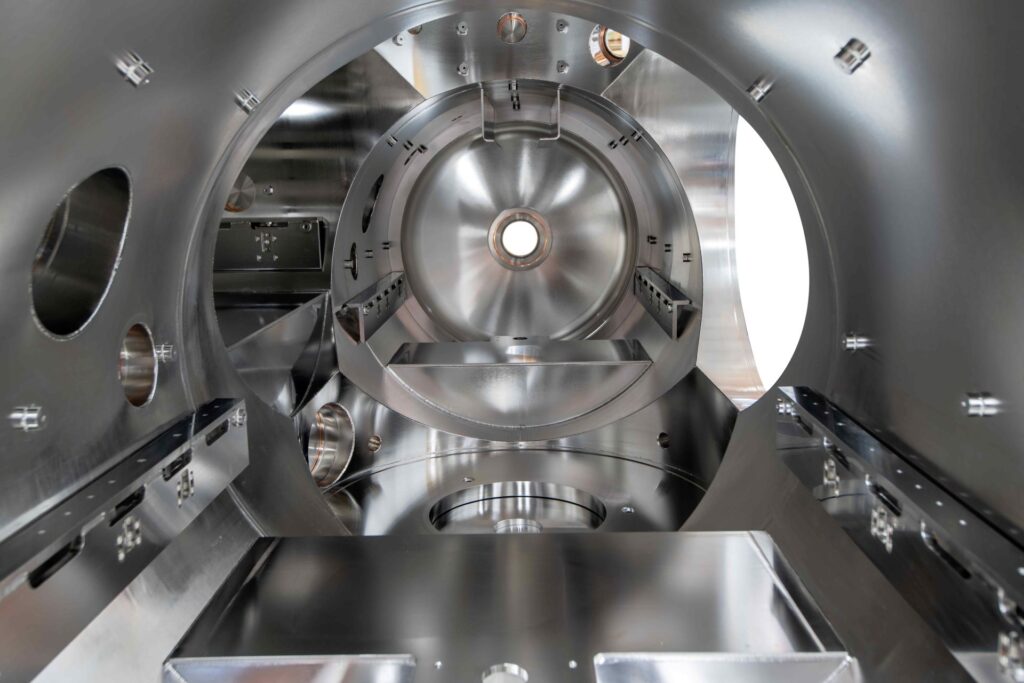

Anderson Dahlen supports the world’s most demanding industries with vacuum vessels that perform under the toughest conditions. We work closely with customers across a variety of market sectors: scientific instrumentation, semiconductor, vacuum coating, aerospace, fusion energy, nuclear, quantum computing, and numerous institutions for energy and material research. Our chambers meet precise requirements for special alloy considerations, structural integrity, dimensional tolerances, surface finish specifications, helium leak test performance, and long-term reliability. From early design support to final assembly and testing, Anderson Dahlen is your single-source partner for vacuum components, chambers, and integrated assemblies.

When it comes to vacuum chamber fabrication, precision isn’t just a benchmark, it’s the bare minimum. Micron-level imperfections can derail entire experiments, compromise semiconductor yields, or lead to catastrophic test failures. That’s why research institutions, aerospace companies, and national labs repeatedly choose Anderson Dahlen for their vacuum chamber projects.

Backed by a rich history in stainless steel fabrication, ASME pressure vessel compliance, and deep experience across critical industries, Anderson Dahlen merges world-class craftsmanship with ultra-high vacuum (UHV) expertise to produce chambers that perform flawlessly under the most extreme conditions.

1. Precision Fabrication Ensures Dimensional Integrity

Every vacuum chamber is subject to distortion from the heat of welding. Holding tolerances post-weld means designing and machining with deformation in mind.

“A vacuum chamber is not just a standard weldment. Once you weld it, things move,” explained Perry Henderson, Business Unit Director. “We engineer in compensation, tolerances, and control to ensure the finished part still meets critical vacuum standards.”

Whether it’s maintaining 0.003″ flatness across a large UHV flange or preserving the perfect roundness of a beamline interface, Anderson Dahlen’s in-house CNC machining, custom-built fixturing, and post-weld machining ensure performance-ready geometry at every step.

“Our team doesn’t just fabricate, we design for manufacturability from day one,” added Matthew Blaha, Business Unit Leader. “We account for distortion during welding and use finish machining to return chambers to exact tolerances.”

2. Certified TIG Welders Trained in Vacuum Science

Vacuum welding requires more than certification, it requires fluency in vacuum physics, metallurgy, and contamination control. Many of our welders are certified to ASME Section IX in GTAW (TIG), with additional training specific to vacuum system fabrication. We have 54 welders holding over 1000 individual welder qualifications. “Welders here are specially trained not just for strength, but for vacuum science, how metals behave, outgas, and how impurities affect performance,” said Blaha.

“You can’t wing this,” added Henderson. “Upon request, we perform welding with mapping, tracking, and documentation to make sure it performs under UHV conditions.” Chambers can include full weld mapping, traveler documentation, and traceable materials certification. This isn’t just high-integrity fabrication, it’s science-backed manufacturing.

3. Expertise With Critical Vacuum Materials

Vacuum systems often require exotic and dissimilar metals, each with unique challenges. From cryogenic cycling to high-temperature bake-outs, materials must retain integrity across extreme conditions. “We routinely work with dissimilar metals in the same build,” said Corey Ragsdale, Senior Business Development Manager. “You can’t just weld them and hope they hold. We bring science into each joint.”

Anderson Dahlen works with 304L/316L stainless steel, aluminum alloys, Inconel, and titanium. Each metal demands precise prep, specific filler, and expert joint design. “We understand how each material responds under vacuum load, heat stress, and cleaning cycles,” added Blaha. “That’s what allows us to build systems that don’t just function, but endure.”

4. In-House Helium Leak Testing to 1×10⁻⁹ atm·cc/sec

Helium mass spectrometry is the industry gold standard for vacuum integrity. At Anderson Dahlen, every weldment undergoes in-house helium testing, eliminating the need for outsourcing. “We don’t ship anything that hasn’t passed helium testing,” said Blaha. “If it leaks, it doesn’t leave.”

Chambers are tested down to 1×10⁻⁹ atm·cc/sec using state-of-the-art leak detection systems. In addition, the facility performs:

- Pressure decay and proof pressure testing

- Thermal bake-out validation

- Documentation and pass/fail records for QA

“Having that in-house lets us control quality and timelines,” Ragsdale noted. “Customers don’t have to wonder, it either meets spec, or we fix it before it ever ships.”

5. Design Collaboration Starts On Day One

One of Anderson Dahlen’s greatest strengths is its collaborative design philosophy. Customers don’t just hand over drawings, they gain a partner in performance optimization. “We’re not just order takers. We partner on design,” Henderson said. “Our customers appreciate that we think five steps ahead, especially when it affects downstream vacuum performance.”

From flange spacing and weld access to port locations and material selection, our team advises early to reduce fabrication risks and improve functionality. “We’ve saved projects just by asking the right questions early,” said Blaha. “It’s about seeing the whole system, not just the part.”

6. Fully Integrated Vacuum Fabrication and Testing Facility

Most shops outsource key steps, which can lead to timeline gaps, quality discrepancies, and blame-shifting. At Anderson Dahlen, everything is done in-house.

Core capabilities include:

- Waterjet and laser cutting

- CNC machining (turning, milling, boring)

- Certified welding

- Passivation

- Helium leak testing

- Final QA, packaging, and documentation

“Having everything in-house means tighter control, better scheduling, and no blame games,” said Ragsdale. “If something’s off, we fix it, right here, right now.”

According to Derek Samborski, ASME Welding Manager, “Vertical integration isn’t just about efficiency. It’s about consistency, and our customers notice the difference.”

7. Trusted by the World’s Most Demanding Industries

Anderson Dahlen isn’t new to high-stakes manufacturing. Our customers span industries where failure simply isn’t an option. “We’ve delivered vacuum systems that have gone into space simulations and extreme cryogenic environments,” said Henderson. “It’s not about just making a box, it’s about building something that never fails under pressure.”

Blaha elaborated, “We’re unique because we know how to build chambers that meet both vacuum best practices and ASME code stress requirements. That’s extremely rare.”

Customers include:

- National laboratories and research facilities

- Semiconductor OEMs

- Aerospace primes

- Cryogenic and superconducting system developers

- Quantum computing startups

This legacy is rooted in a company history that spans over 75 years. Carter Anderson, Business Development Manager, summed it up: “The DNA of this place is problem solving. That’s how we built a reputation for taking on the hard jobs and delivering.”

Vacuum-Ready, Science-Driven Fabrication

Anderson Dahlen doesn’t just weld parts together, they engineer precision systems. Their strength lies in bringing together:

- ASME code compliance

- Ultra-high vacuum requirements

- Exotic metal knowledge

- Design-for-manufacture expertise

- Fully documented quality assurance

“We bring together the ASME strength calculations and the vacuum chamber best practices. That’s what makes us different,” said Blaha.

From post-weld machining to helium leak testing, from exotic alloys to dissimilar metal joints, Anderson Dahlen has developed systems that perform with scientific precision. “Every step is intentional,” said Anderson. “Customers don’t just get a fabricated part, they get a partner who understands what’s at stake.”

Let’s Build Your Next Vacuum Chamber

If you’re designing a vacuum system or need a fabrication partner you can count on, Anderson Dahlen is ready. Let’s talk about your specs, your timeline, and your performance expectations. We’ll bring the engineering, materials expertise, and fabrication excellence to meet your goals with confidence.

Whether you’re designing a one-off research vessel or scaling up for commercial production, Anderson Dahlen is ready to meet the challenge. Contact the team to discuss your next vacuum welding or fabrication project and discover why the world’s most demanding industries trust Anderson Dahlen for their most critical projects.