Celebrating Safety Month at Anderson Dahlen

At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Home » The Power of Steam

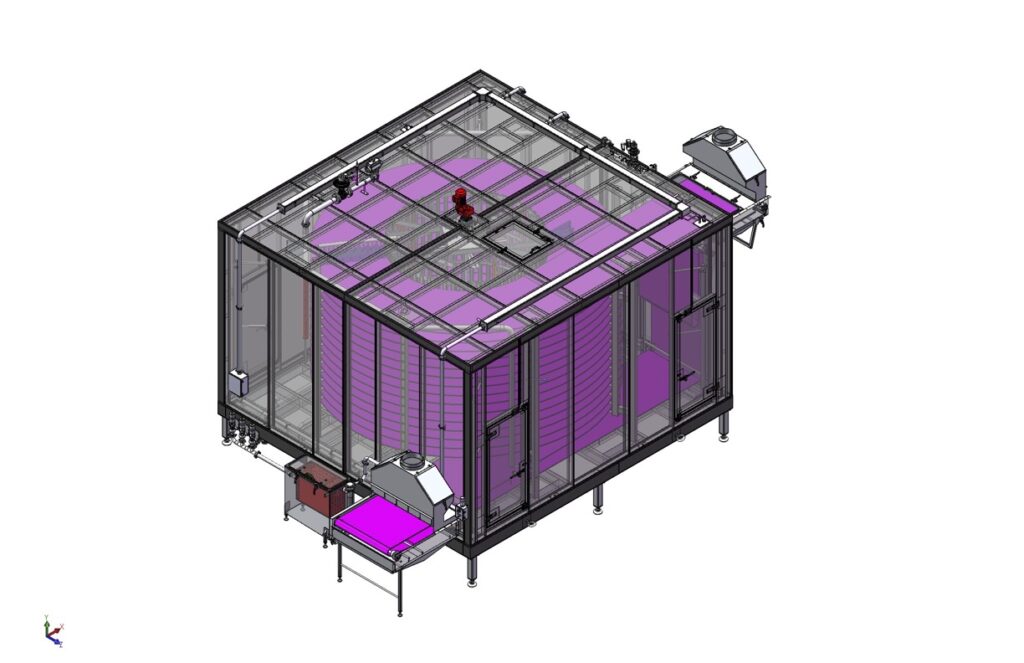

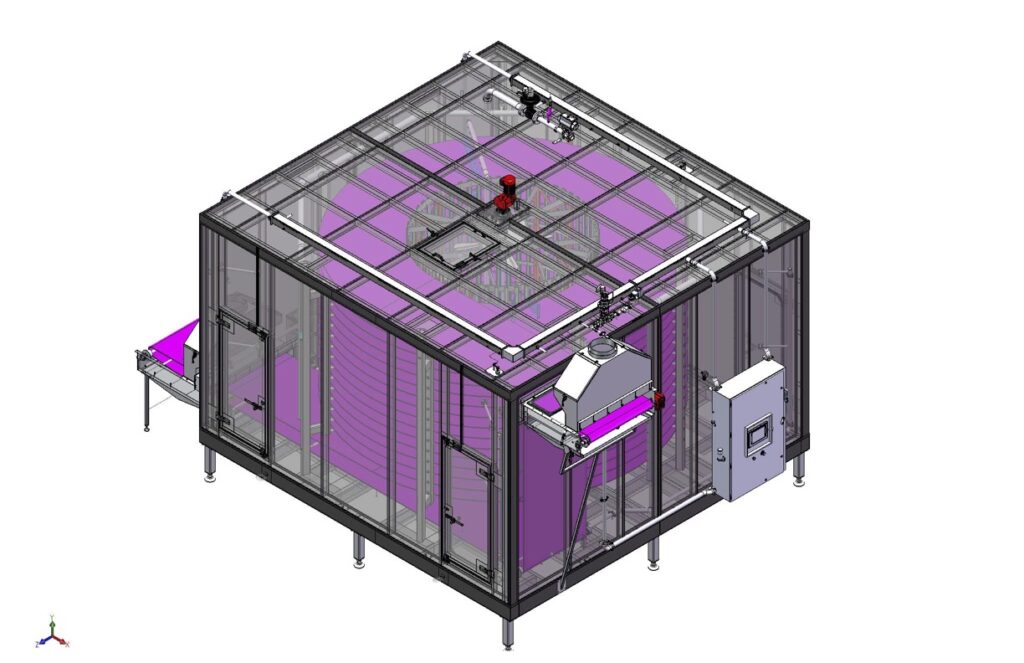

Anderson Dahlen’s Spiral Steam Ovens and Booster Steam Ovens provide innovative cooking solutions to improve food processing while ensuring strict food safety standards. These steam ovens operate using gentle and continuous cooking technology, which stands apart from traditional high-temperature methods. This technology improves yield and product consistency while also cutting operational expenses.

Traditional cooking techniques use high temperatures and dry heat, which reduce yields, increase energy usage, and demand significant maintenance. Anderson Dahlen’s Spiral Steam Ovens use a spiral conveyorized cooking system that injects live steam, allowing food products to cook evenly at a controlled temperature.

Anderson Dahlen’s Spiral Steam Ovens have been successfully integrated into large-scale food processing operations, such as doubling the volume of canned poultry production, optimizing tamale cooking, and improving consistency in bagel steaming.

Booster Steam Ovens enhance high-temperature cooking lines alongside full-scale steam ovens. By placing these compact, rapid steamers either at the start or end of their production lines, manufacturers can bolster production line throughput and maintain food safety.

A large food processing company implemented Booster Steam Ovens in its sausage production line to maintain accurate core temperatures without burning the outer layer. A minor change to their production process solved an essential food safety problem without sacrificing production speed.

While Spiral and Booster Steam Ovens are widely used in meat processing, their applications extend far beyond poultry, beef, and pork. Many food manufacturers use these systems for delicate, high-yield cooking applications, including:

One of the standout features of Anderson Dahlen’s Spiral and Booster Steam Ovens is their effortless integration into new and existing food production lines. Designed to be flexible, these ovens can be adapted to meet the unique layout, speed, and space constraints of a wide range of processing environments.

Whether a company is retrofitting legacy systems or building out new production lines to meet rising demand, Anderson Dahlen’s steam ovens offer custom solutions. They can be engineered to align with conveyor belt speeds, accommodate specific product transfer requirements, and synchronize with upstream and downstream equipment, including high-temperature linear ovens, spiral freezers, searing units, and post-packaging systems.

The ovens’ modular design allows for simplified integration with minimal disruption. Their ability to cook gently yet efficiently enhances the overall thermal profile of the production line while preserving product appearance, moisture, and texture. Even in highly space-sensitive environments, the compact footprint of these ovens makes them an excellent choice for operations that need to scale without major facility modifications. This design ensures that manufacturers maintain efficiency and food safety and extend the lifecycle of their existing equipment investments.

Whether you want to increase production, improve food safety, or optimize yield, Anderson Dahlen’s Spiral Steam Ovens and Booster Steam Ovens offer an efficient and cost-effective solution. Contact us to learn how steam cooking can work for your business.

At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Why Having Critical Components on Hand Matters Manufacturing is a time-sensitive business where preventable equipment failures can cause production lines to stop running and lead

Understanding the Difference: Fabrication vs. Machine Shops One of the most common questions from prospective customers is: “Are you a machine shop or a fabricator?”

Anderson Dahlen built an ultra-high vacuum chamber used for growing thin films, typically of refractory materials, using a high temp deposition process. Critical tolerances are

Meet our new Business Development Manager, AJ! AJ is from Moorhead, MN, and earned a B.S. in Mechanical Engineering from the University of North Dakota.

Meet Wyatt Craft, our new Business Development Manager! Wyatt received a Bachelor’s degree in Global Business from Saint John’s University and has three years of

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.