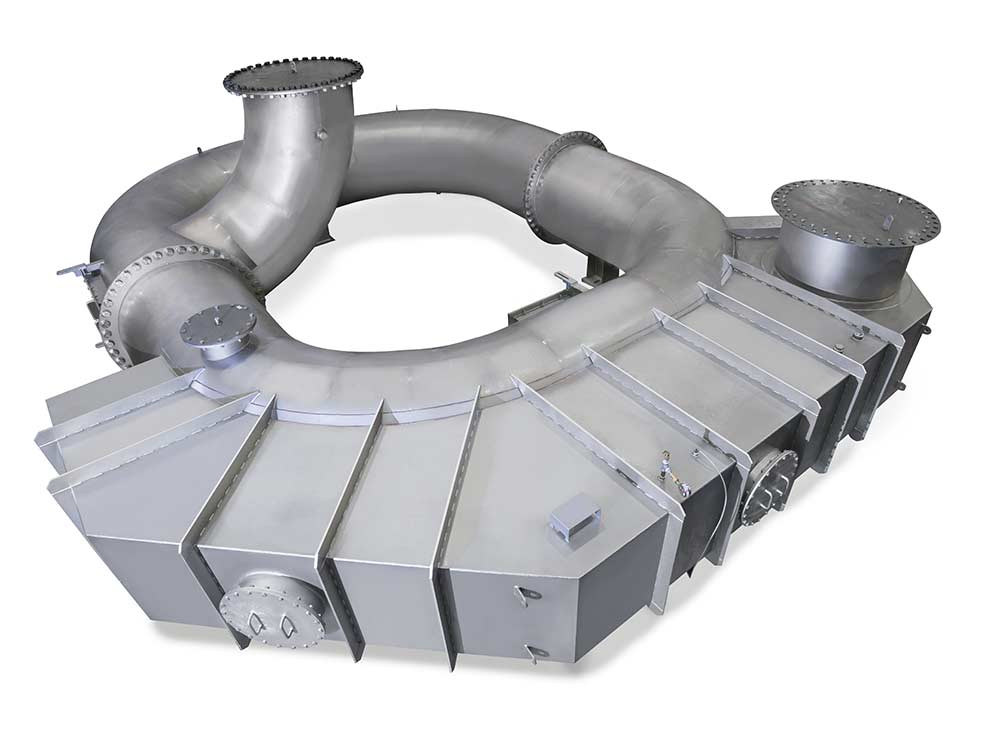

Anderson Dahlen partners with companies across diverse industries to provide industrial equipment that meets the highest standards. We take pride in our ability to provide welding, CNC machining, finishing, cutting, and other fabrication services.

Our experience ranges from a variety of mixing and blending applications, ASME vessels, conveying, reactors, refining, and separating of liquid or dry materials. We also fabricate components and assemblies for nuclear facilities. With in-house engineering, stainless steel fabrication services, and a commitment to innovation, our turnkey offerings for custom parts and equipment are designed to meet your critical specifications.

We take quality seriously. Our project managers and certified welders ensure every detail of your project is engineered, fabricated, documented, and inspected to your specifications. Weld procedures, surface finish criticality, and post-weld features are carefully managed to minimize corrosion and contamination risks. This focus, combined with continuous improvement, ensures that your project will be completed on time and within budget.

Comprehensive systems to treat, recycle, and manage water resources, ensuring sustainability and compliance across industrial operations.

Precision-engineered systems to safely mix, process, and manage chemical products at scale.

Delivering durable, high-performance equipment engineered for demanding oilfield conditions.

Streamline your facility’s operations with efficient, high-quality production processes.

Engineered to handle liquids and materials precisely, supporting both batch and continuous processes.

Improve operational efficiency with systems designed to maximize throughput, minimize downtime, and integrate seamlessly into your environment.

Ensure every system meets performance standards through comprehensive testing before it enters your facility.

Optimize water management with reliable, efficient treatment systems for industrial operations.

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.