One of the most challenging practices in manufacturing is knowing your limitations. How much can you build in-house? How much time and resources are you willing to invest in building the components your business depends on? And perhaps most humbling, what are the limitations of your team’s technical expertise?nbsp;

Some businesses have run themselves into the ground because they needed help to step back and objectively decide where to draw that line. And we get it. We know how hard it can be to turn over the design and build of your most critical components to anbsp; contract OEM manufacturer.nbsp;

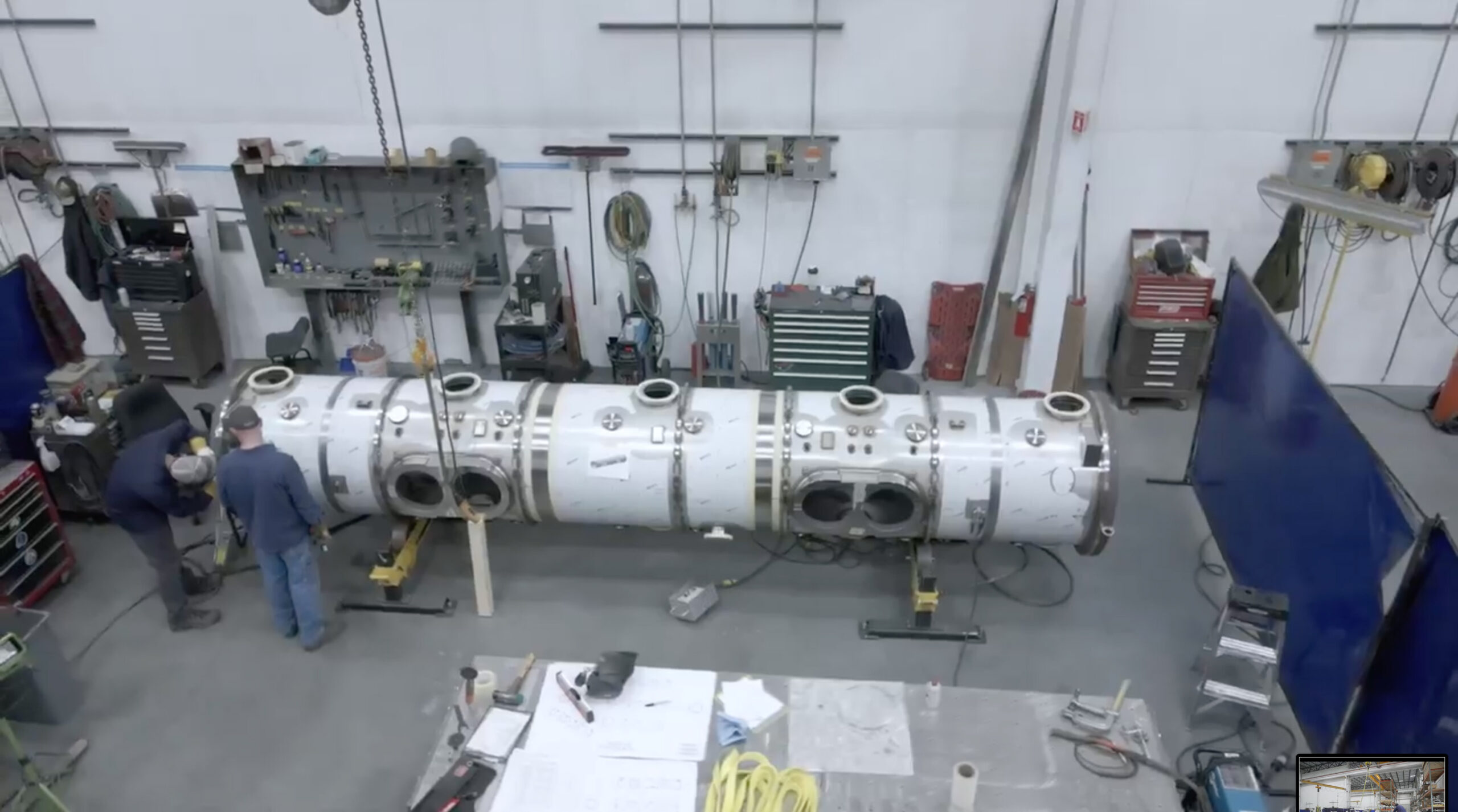

That’s where Anderson Dahlen comes in to provide our global partners the capacity and unmatched expertise to improve their product’s design, reduce production costs, and improve product quality. Here’s how.

What’s At the Heart of OEM Manufacturing?nbsp; nbsp;

The heart of OEM Manufacturing is not just about building and delivering equipment. A dependable OEM partner can provide much more, including:

That’s more than just engineering and manufacturing. It’s creating peace of mind, something that you simply can’t fabricate.nbsp;

On the surface, we’re manufacturing highly specific equipment tailor-made for each customer, but an OEM manufacturer with the caliber of Anderson Dahlen means not just meeting but exceeding our customer’s needs. And that is the heart of our service: not only are we providing high-quality projects but also building trust and dependability.nbsp;

Often this isn’t easy to explain, and it must be experienced to fully appreciate why this is such a vital service for our customers.

Recently, we wrote about this experiencenbsp; in an interview with Kaushik Das, an engineer here at Anderson Dahlen. There was the moment when after a journey that began with redesigning, reengineering their project and developing as we built, tested, shipped, and reconstructed a three-story tall piece of equipment at their facility our customer got to turn it on and watch it work.nbsp;

It is rare you get to flip a switch that’s capable of transforming an entire industry. That is the heart of OEM Manufacturing.nbsp; nbsp;

Custom, Full-Scale Production Without Capital-Intensive Investmentsnbsp; nbsp;

Again, knowing when to outsource the design and fabrication of your most critical equipment can take a lot of time and effort.nbsp; One recent project highlights the power of collaborationnbsp; in such a partnership.nbsp;

One of the signature aspects of our several projects with the DeFrancisci Machine Company (Demaco) was, as Joe DeFrancisci put it, a “tremendous strategic advantage for Demaco, [as] our assets and resources are precisely focused on the activities that matter most to customers and as a result, we are outpacing our competition in both innovation and growth. When it comes to quality manufacturing, we are perfectly confident in Anderson Dahlen. Our teams work so well together that each function as a mutually supporting extension of the other.”nbsp; nbsp;

Our OEM Process is such that Anderson Dahlen could be considered an extension of our partner’s company. So much so that, for many years, Demaco has increasingly relied on Anderson Dahlen’s OEM manufacturing service. It allows them to focus their own resources on designing and servicing equipment specific to end customer needs.

Knowing when to outsource your OEM manufacturing needs is one thing. But choosing a partner that can vastly increase your production capacity as if it were an extension of your own company (without the intensive capital investment of going it alone) made the difference for Demaco.

Learn More About OEM Manufacturing at Anderson Dahlennbsp; nbsp;

If you’re interested in learning more about our OEM capabilities, contact Anderson Dahlen today.nbsp;