Vacuum Products for Advanced Research and Manufacturing

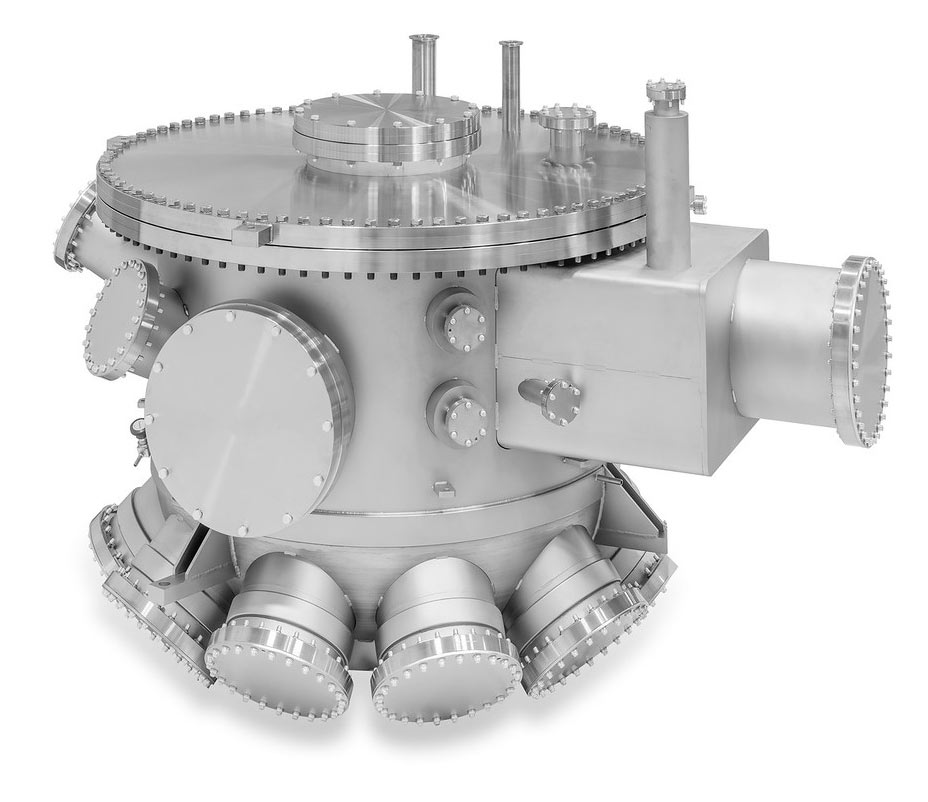

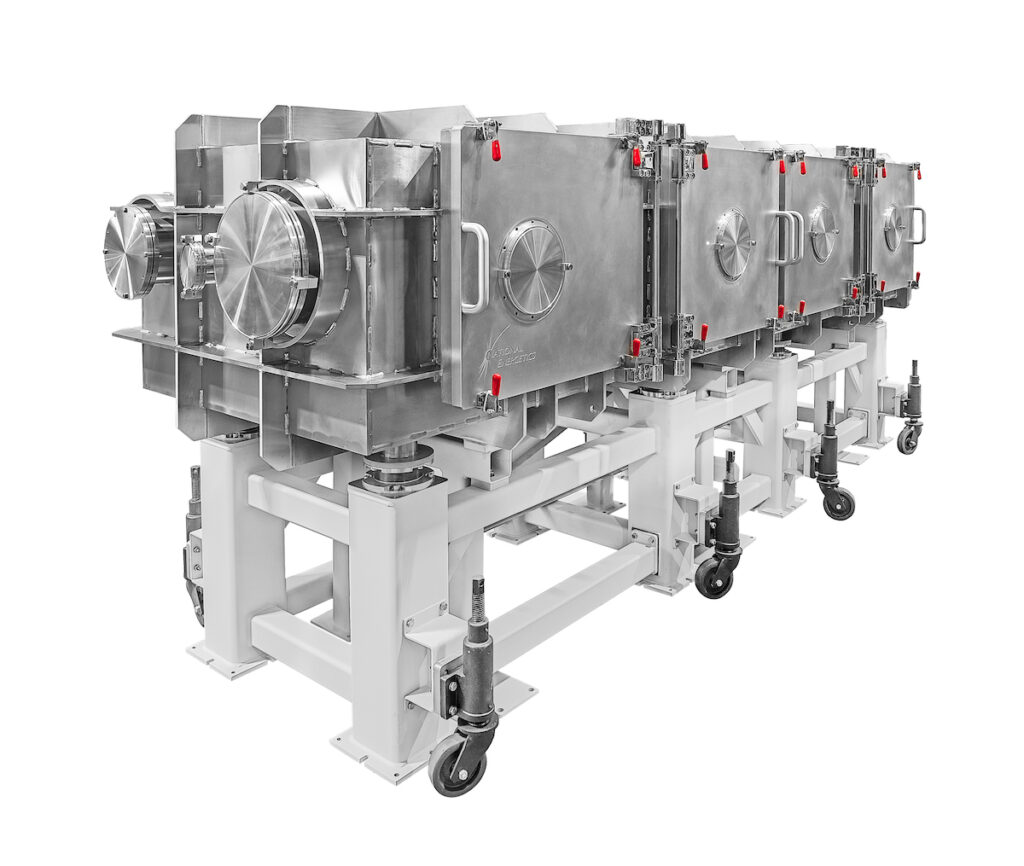

From industrial to extreme high vacuum (XHV) products, Anderson Dahlen’s engineering and manufacturing capabilities produce the ideal solutions to meet your needs. We offer a wide range of custom-built solutions, such as flanges and components, custom vacuum systems, custom high vacuum chambers, XHV chambers, and UHV chambers.

No matter the complexity of your project, Anderson Dahlen provides the manufacturing expertise to effectively integrate equipment. We produce all chambers and supports in-house, giving us control over design, quality, and fit. This way you receive the best value and performance for your equipment.

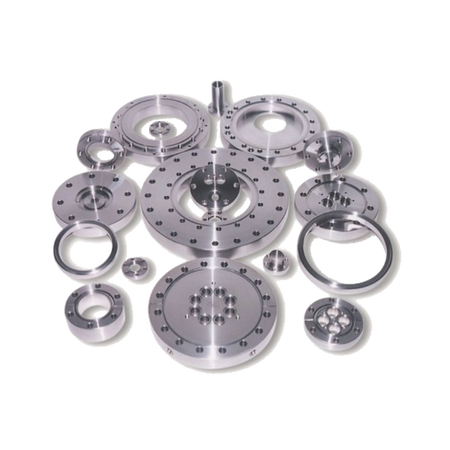

Flanges and components are critical to any high vacuum (HV) or ultra-high vacuum (UHV) system. Standard components are convenient but only sometimes the optimal solution. When standard parts are insufficient, Anderson Dahlen has the engineering and manufacturing capabilities to produce the ideal product to meet your requirements.

You deserve only the highest quality products, which is why Anderson Dahlen ensures our team has the proper certifications. Some of our key certifications include:

When you partner with Anderson Dahlen for your upcoming projects, expect only the highest quality.

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.