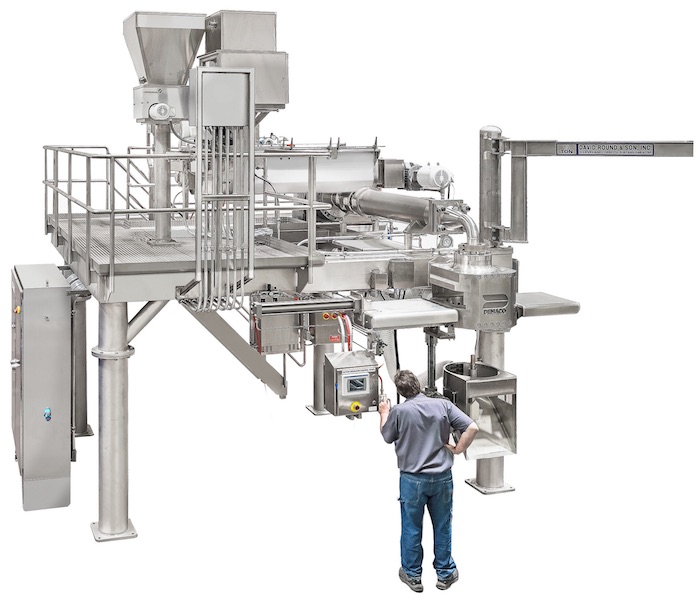

Successful partnerships allow companies to focus their resources on core strengths, resulting in optimum value for end customers. Anderson Dahlen and the De Francisci Machine Company (Demaco) have been in business together for over 20 years. The formation of a strong partnership has allowed both businesses to gain significant market share and successfully complete numerous large-scale projects.

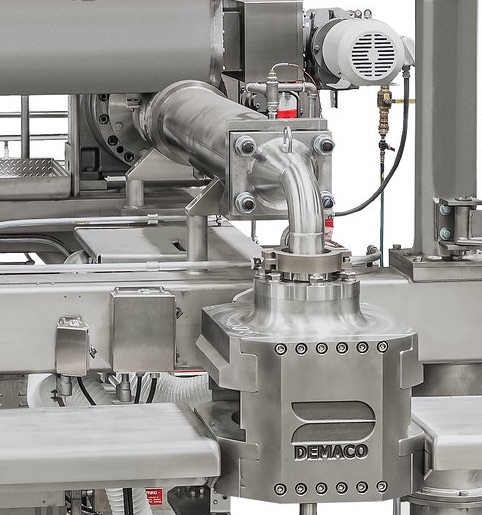

Demaco is an industry leader in manufacturing sanitary pasta extruders for prepared foods and fresh pasta. With over 100 years of operation, they have developed technology and solutions that provide lasting customer value and produce superior food products.

“Our partnership with Anderson Dahlen has allowed us to direct our resources into customer service, pure engineering, and pasta processing technology. This has been a tremendous strategic advantage for Demaco, as our assets and resources are precisely focused on the activities that matter most to customers and as a result we are outpacing our competition in both innovation and growth,” says Joe DeFrancisci from Demaco. “When it comes to quality manufacturing, we are perfectly confident in Anderson Dahlen. Our teams work so well together that each functions as a mutually supporting extension of the other.”

Demaco has increasingly relied on Anderson Dahlen’s manufacturing resources, allowing their own resources to focus on designing and servicing equipment specific to end customer needs. To meet Demaco’s high standards, Anderson Dahlen controls as much of the fabrication as possible within their own facility. This includes certified welding, which is qualified to American Welding Society (AWS) and American Society of Mechanical Engineers (ASME) welding procedures.

The combined engineering teams have decades of experience with pasta equipment and other food manufacturing applications – mixers, extruders, skid systems, full production lines, and turnkey plant operations. Production systems are continually modernized to improve costs, production output, efficiency, and industry regulation compliance. Every end-customer has specific requirements which are incorporated into a specific test and approval process, typically involving factory visits during the project and for final acceptance.

Demaco and Anderson Dahlen share a common goal – to deliver the highest standard of products and to be an active partner in our customers’ success. We help food producers stay at the forefront of technology, quality, and productivity by providing superior customer service, excellent engineering and fabrication services, and the highest quality equipment.

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795