The Advanced Photon Source (APS) at the U.S. Department of Energy’s Argonne National Laboratory provides ultra-bright, high-energy, storage ring-generated x-ray beams for research in almost all scientific disciplines. An important part of the facility consists of undulators that are used to maximize key x-ray beam qualities vital to frontier experimentation. Undulators are magnetic devices that can be found in all modern synchrotron light sources.

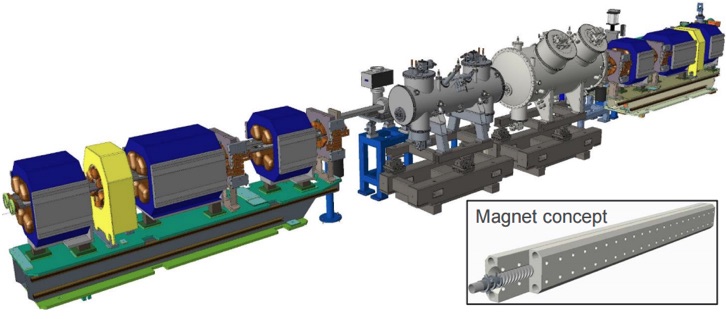

While there are numerous variations of undulator designs (magnet dipole orientation, in-vacuum/out-vacuum, superconducting/non-superconducting, etc.), the general purpose of an undulator is to generate beam oscillations for the production of synchrotron radiation. The radiation produced is a bright, collimated beam that can be utilized (even tuned) for various types of research that include medical applications, imaging, and lithography. The APS is developing novel superconducting undulators to advance the state of the art in this technology.

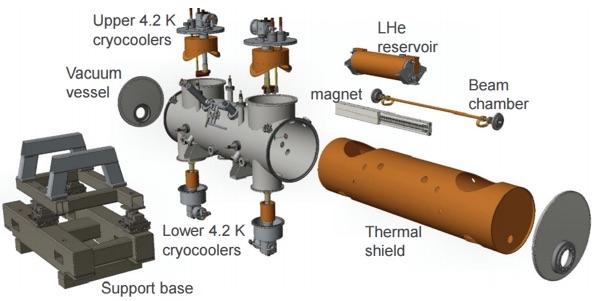

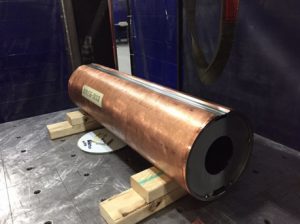

Anderson Dahlen was awarded a build-to-specification contract for the latest Helical Superconducting Undulator (HSCU) cryostat consisting of a vacuum vessel, thermal shield, and ASME code stamped liquid helium reservoir. Currently, there are two SCUs installed on the APS ring, and the latest additional has been developed with a new helical magnet configuration and cryostat design. The HSCU cryostat has been redesigned to achieve a smaller (less expensive) vacuum vessel, single thermal shield, and a simplified liquid helium circuit and cryocooler-based refrigerator system. Use of standard ISO LF and conflat flanges and tube sizes further reduced complexity and cost.

Anderson Dahlen was tasked with finalizing the mechanical design and fabrication of the HSCU cryostat on a build-to-spec basis. In addition to the vacuum requirements for the vessel and shield, Anderson Dahlen was also required to design and certify the liquid helium reservoir in accordance with ASME Section IX of the Boiler and Pressure Vessel Code for cryogenic applications.

View More Projects

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795