Celebrating Safety Month at Anderson Dahlen

At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Home » Positive Displacement Pump Prevents Particle Build Up

Universal 3 Series Positive Displacement Pump

Industry/Application:

Industry/Application:

A major processor of sauces, dressings, and dips uses positive displacement (PD) pumps to transfer its products that contain suspended particulates such as tomato, onion, pepper pieces, garlic, basil, and salt.

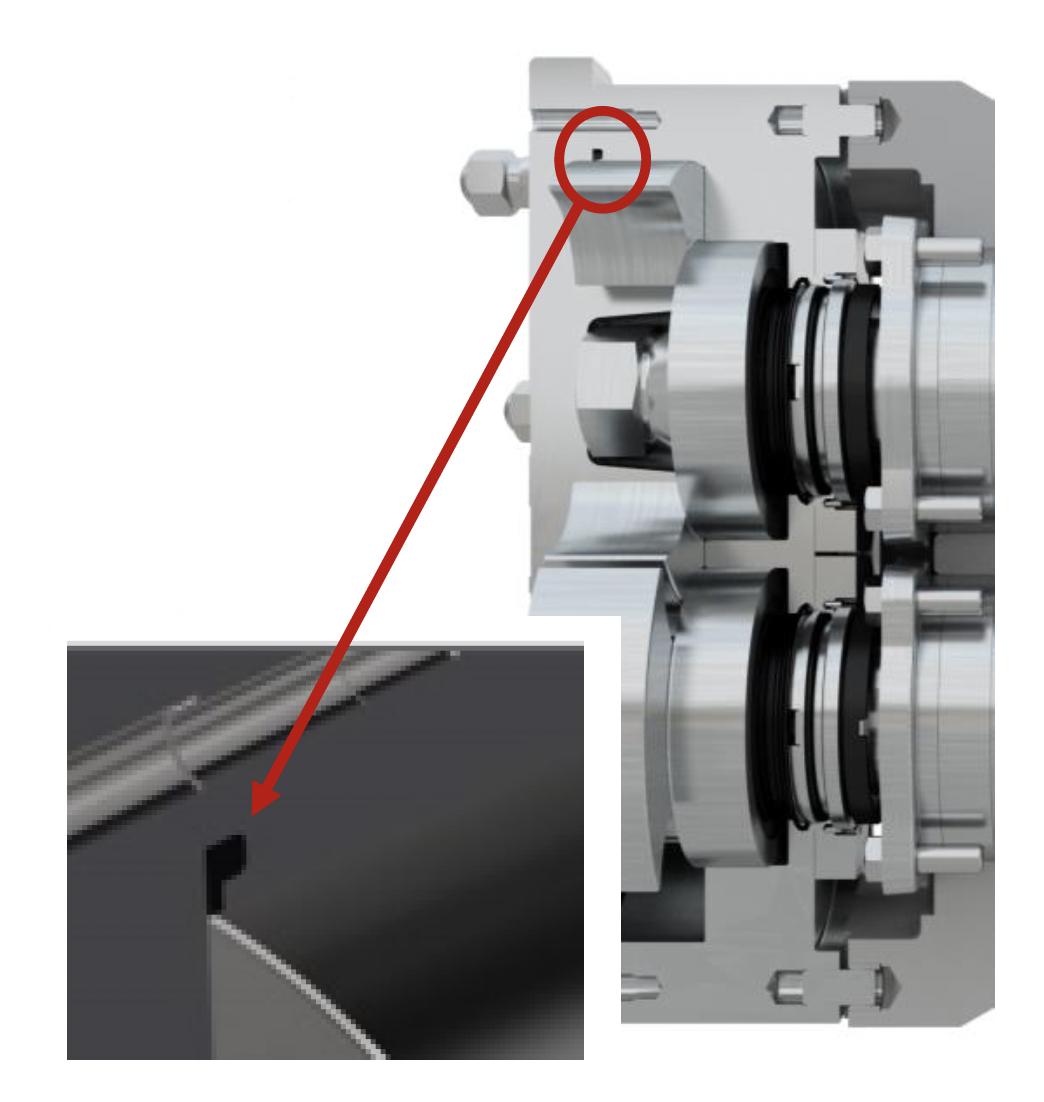

Problem: The customer* had been using PD pumps in their process lines for many years. However, after a period of time, they discovered small ingredient particulates beginning to accumulate around the cover O-ring even after completing the clean in place (CIP) cycles giving rise to a risk of contamination. Sanitation personnel were then forced to open and further clean the pumps manually (on designs meant to be fully CIP-able) – delaying production times significantly. Solution: The customer tested a Waukesha Universal 3 PD Pump that utilizes a L-shaped gasket in the front of the body which mates up with the flat pump cover, preventing particles from accumulating. The customer ran multiple test products and CIP solution through a model U3 size 045. After each run, the pump was disassembled for inspection and no accumulation around the L-gasket was found. Result: The customer was delighted with the results and has informed SPX FLOW that they are making plans to replace other pumps with the Waukesha Universal 3 series. As an additional benefit, U3 pumps use the same shaft seals for model sizes 30-130, helping to further reduce spare parts inventories. * Company name not disclosed for confidentiality reasonsAt Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Why Having Critical Components on Hand Matters Manufacturing is a time-sensitive business where preventable equipment failures can cause production lines to stop running and lead

How Spiral and Booster Steam Ovens Are Transforming Food Processing Anderson Dahlen’s Spiral Steam Ovens and Booster Steam Ovens provide innovative cooking solutions to improve

Understanding the Difference: Fabrication vs. Machine Shops One of the most common questions from prospective customers is: “Are you a machine shop or a fabricator?”

Anderson Dahlen built an ultra-high vacuum chamber used for growing thin films, typically of refractory materials, using a high temp deposition process. Critical tolerances are

Meet our new Business Development Manager, AJ! AJ is from Moorhead, MN, and earned a B.S. in Mechanical Engineering from the University of North Dakota.

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.