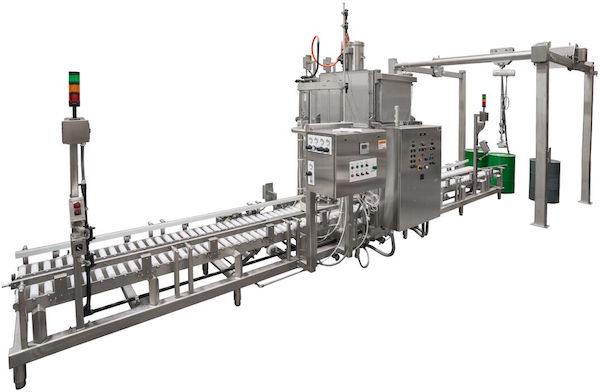

When you work with Anderson Dahlen on a turnkey equipment solution, we take single source responsibility for the project’s success and results, saving you time and frustration by eliminating the need to coordinate with several vendors. From the beginning, our teams will work together to review and analyze the existing system, process, layout, regulations, and quality requirements. This includes engineering, project management, fabrication, manufacturing, welding, assembly, testing, and installation.

You’ll get the finishes, documentation, and traceability your project requires without any hassle. With over 200 welding procedures that are certified to the ASME or AWS welding codes using aluminum, carbon steel, stainless steel, nickel alloy, duplex stainless steel, and other dissimilar metals, we can handle your most complex project.

Factory Acceptance Tests (FATs) are just one piece of the complete list of inspections, quality checks, and verification we do to ensure high standards are met and a quality final product is delivered. FATs take place prior to ship, so when you receive the final product, there will be minimal downtime to install it.

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795