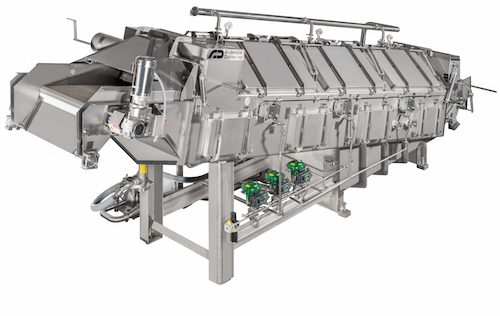

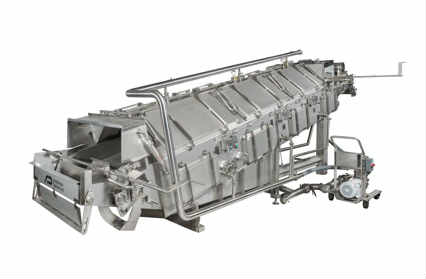

Our high-volume cooking solutions allow food and pharmaceutical companies to utilize the efficiency and purity of steam cooking, improving quality and production volume. At the same time, they reduce cooking time, waste, and maintenance costs. By integrating linear steamers and Checker Spiral Steam Ovens into their production lines, they are increasing overall yields.

Our spiral and linear steam cookers are customized based on temperatures, cooking times, and the application itself, making them unmatched for maintaining food weight, moisture, nutritional content, and flavor.

Checker Sprial Steam Ovens deliver more cooking power, in less space, at a lower cost. They are an efficient and economical way to pasteurize ready-to-eat (RTE) meat and poultry products. The flavor of the RTE product is retained by minimizing pasteurization time and precisely controlling the temperatures.

There are applications that require non-steam methods. Our engineers will help address custom requirements for your cooking process from radiant or convection to thermal jackets or heat platens.

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.