Celebrating Safety Month at Anderson Dahlen

At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Home » Revolutionizing Fusion Energy: A Groundbreaking MIT Collaboration Using Anderson Dahlen Vacuum Chambers

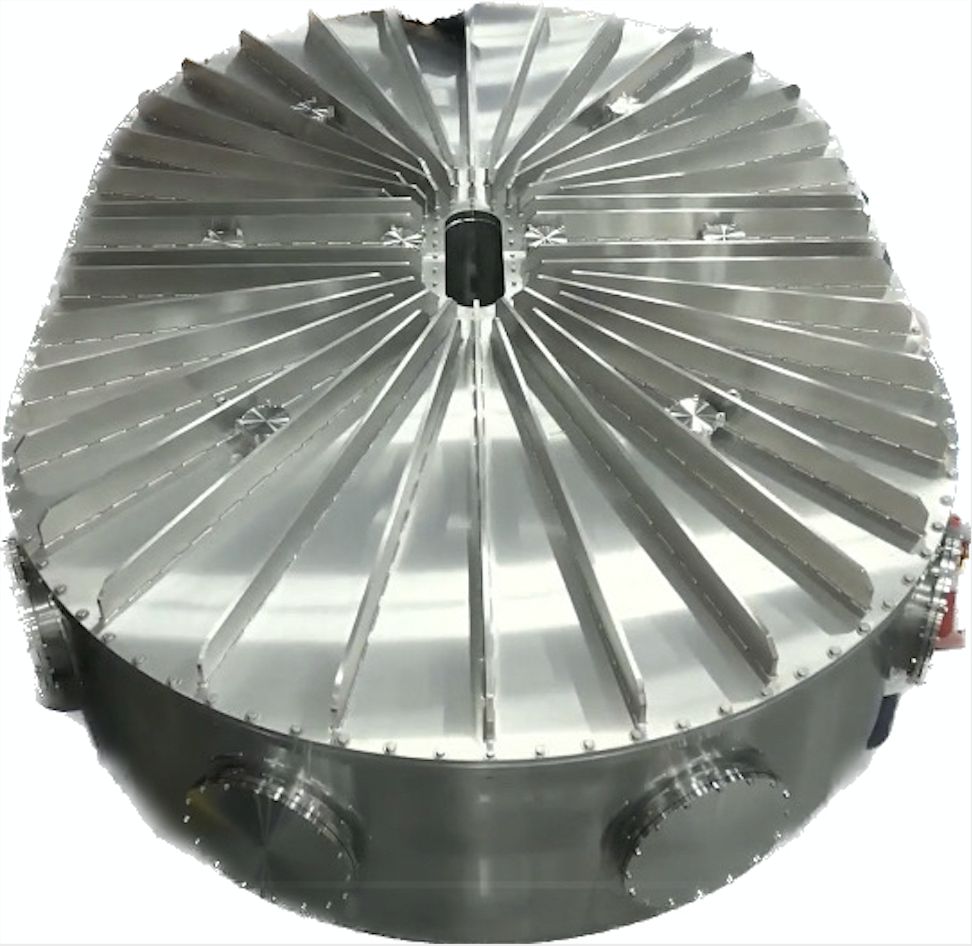

MIT and Commonwealth Fusion Systems, using a custom vacuum chamber built by Anderson Dahlen, are paving the way for the future of fusion energy. Their joint efforts in developing high-temperature superconducting magnets have culminated in a revolutionary breakthrough, promising the potential for a compact and economically viable fusion power plant in the near future.

A central piece of this research was Anderson Dahlen’s creation of a state-of-the-art vacuum chamber. Between May 2020 and March 2021, the team crafted a main vacuum vessel that stands as a testament to engineering excellence. Made from dual-certified 304/304 L stainless steel and with an interior volume of approximately 15.3 m³ (539 ft³), this vessel was designed to accommodate the Tokamak Fusion Magnetic Core (TFMC) within the spatial constraints of its installation space.

Anderson Dahlen collaborated closely with the MIT team to translate the MIT design concept for a vacuum vessel and liquid nitrogen cryogenic thermal shield into a manufacturable reality. Because of its sheer size, the concept model had been designed around rigorous structural standards to withstand the significant pressure loading on the vessel. With extensive background in structural and pressure vessel engineering, ADI validated the design during the design for the manufacture stage of the project, working closely with MIT and making use of finite element analysis to verify design decisions, reinforcing Anderson Dahlen’s significant role in advancing fusion energy research.

MITs successful testing of the high-temperature superconducting magnets marked a significant advancement in fusion research. Achieving a world-record magnetic field strength of 20 tesla, these magnets have demonstrated the feasibility of constructing a compact, efficient fusion power plant. This development has the potential to revolutionize global energy production.

Anderson Dahlen’s involvement in this MIT project highlights the importance of collaboration between the industry and scientific research communities. The company’s capability to fabricate complex components such as the vacuum chamber has been crucial to the project’s success, showcasing the essential relationship between engineering expertise and innovative energy solutions.

For more insights into this transformative project, readers are encouraged to explore original articles and resources provided by MIT News and the research teams involved.

Tests show high-temperature superconducting magnets are ready for fusion

At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Why Having Critical Components on Hand Matters Manufacturing is a time-sensitive business where preventable equipment failures can cause production lines to stop running and lead

How Spiral and Booster Steam Ovens Are Transforming Food Processing Anderson Dahlen’s Spiral Steam Ovens and Booster Steam Ovens provide innovative cooking solutions to improve

Understanding the Difference: Fabrication vs. Machine Shops One of the most common questions from prospective customers is: “Are you a machine shop or a fabricator?”

Anderson Dahlen built an ultra-high vacuum chamber used for growing thin films, typically of refractory materials, using a high temp deposition process. Critical tolerances are

Meet our new Business Development Manager, AJ! AJ is from Moorhead, MN, and earned a B.S. in Mechanical Engineering from the University of North Dakota.

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.