Celebrating Safety Month at Anderson Dahlen

At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Home » Dairy Processing Innovations: Custom Solutions by Anderson Dahlen

The dairy industry encompasses an array of products, each with its own processing equipment requirements. Anderson Dahlen’s innovative approach gives us the unique ability to impact the market and focus on the specialized needs of ice cream, cheese, and dairy processing. You can also learn more about our commitment and experience in the industry during this week’s CheeseExpo in Milwaukee, WI – visit us at booth 1824!

Custom Dairy Processing Equipment

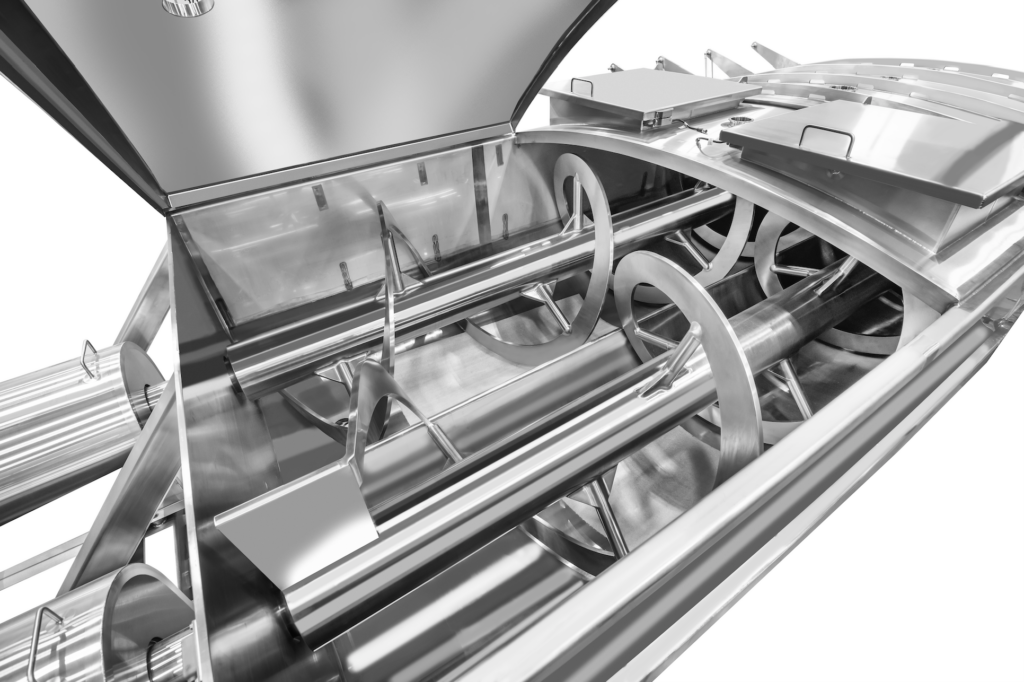

Our team often builds proprietary dairy processing equipment from proven designs, so we have the ability and know the importance of confidentiality for our OEM contract manufacturing partners. If you don’t have a design in mind, our engineers and fabricators can partner with dairy producers to identify the right equipment to meet their processing needs. Whether you have a proven design or need a little advice, our team’s dairy industry experience will ensure your equipment is production-ready.

Adhering to 3A Finish and USDA Standards

Adherence to hygienic design and equipment standards is non-negotiable in dairy processing. Our fabricators excel at achieving a 3A finish—a highly polished, smooth, and easy-to-clean surface crucial for dairy processing equipment—ensuring that all products meet the highest hygienic and safety standards. This meticulous attention to detail facilitates easier maintenance and cleaning while significantly reducing the risk of contamination, a critical consideration in dairy processing.

Keeping it Clean

Even after the equipment is designed and built with sanitary standards in mind, you still need to maintain its cleanliness. Anderson Dahlen’s Clean-in-Place (CIP) and Clean-out-of-Place (COP) solutions are designed to exceed the stringent industry regulations, providing dairy processors with automated systems that ensure impeccable cleanliness with reduced resource consumption. Our expertise in crafting custom CIP and COP solutions demonstrates a deep understanding of the dairy industry’s needs, marrying regulatory compliance with operational efficiency.

Transforming Cheese Production with Tailored Solutions

Cheese production, known for its intricate processes and stringent quality standards, demands precision and adaptability. Anderson Dahlen’s custom fabricated components and integrated equipment ensure that cheese producers can balance tradition and modern efficiency, from curd processing to whey processing and beyond.

Innovating Milk Processing for Enhanced Quality and Efficiency

Milk processing stands at the core of the dairy industry, requiring equipment that can handle everything from pasteurization to homogenization and packaging. Our tailored solutions for milk processing highlight our commitment to enhancing efficiency without compromising on quality. Our advanced manufacturing capabilities allow for the design and fabrication of equipment that meets the need of milk producers, from small-scale farms to large dairy conglomerates.

Meeting the Unique Needs of Ice Cream Production

Ice cream, a beloved treat with complex processing requirements, benefits significantly from Anderson Dahlen’s experience and partnerships with key sanitary parts distributors. Our experience with sanitary pumps, like the Waukesha Model 130 Universal 1 Series highlights our ability to work with ice cream and other dairy products. Learn more about how we optimized an ice cream mix system to enhance operational efficiency and reduce cost.

At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Why Having Critical Components on Hand Matters Manufacturing is a time-sensitive business where preventable equipment failures can cause production lines to stop running and lead

How Spiral and Booster Steam Ovens Are Transforming Food Processing Anderson Dahlen’s Spiral Steam Ovens and Booster Steam Ovens provide innovative cooking solutions to improve

Understanding the Difference: Fabrication vs. Machine Shops One of the most common questions from prospective customers is: “Are you a machine shop or a fabricator?”

Anderson Dahlen built an ultra-high vacuum chamber used for growing thin films, typically of refractory materials, using a high temp deposition process. Critical tolerances are

Meet our new Business Development Manager, AJ! AJ is from Moorhead, MN, and earned a B.S. in Mechanical Engineering from the University of North Dakota.

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.