Celebrating Safety Month at Anderson Dahlen

At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Home » Positive Displacement Pumps Solve Ice Cream Mix System Issue

Industry: Ice Cream Mix

Problem: Premature failure of rotors and shaft parts

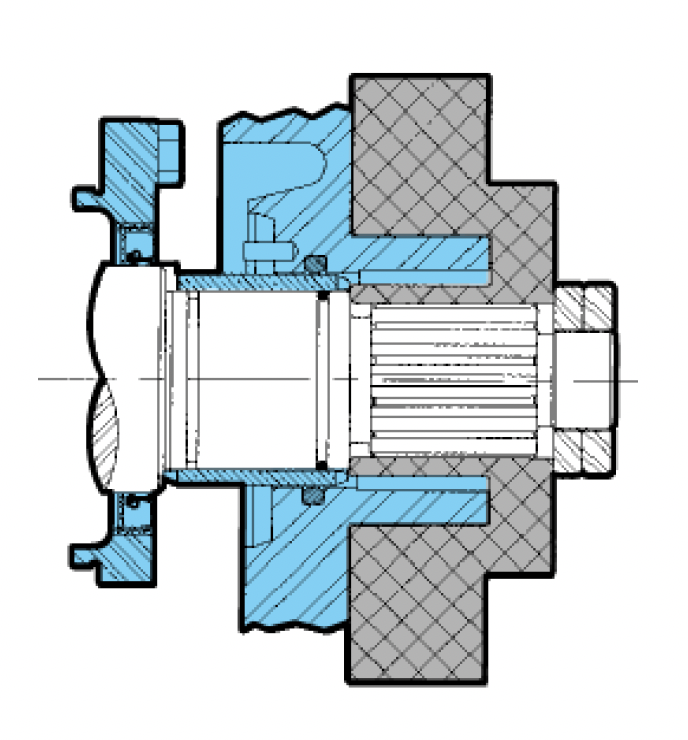

Solution: A large US-based dairy installed an ice cream mix system using two Waukesha model 130 Universal 1 series pumps with the help of SPX; one as a feed pump and the other as a pullout pump for a dry/liquid blender.

The plant was interested to reduce the cost of ownership of the rotary lobe pumps from a previously installed system. The pumps used in the original system required complete rotor replacement every 6 months.

Industry: Ice Cream Mix

Problem: Premature failure of rotors and shaft parts

Solution: A large US-based dairy installed an ice cream mix system using two Waukesha model 130 Universal 1 series pumps with the help of SPX; one as a feed pump and the other as a pullout pump for a dry/liquid blender.

The plant was interested to reduce the cost of ownership of the rotary lobe pumps from a previously installed system. The pumps used in the original system required complete rotor replacement every 6 months.

The External Circumferential Piston (ECP) style rotors, with larger crossover clearances and higher efficiency, were able to stand up to the plant’s demanding performance requirements and eliminate their pump downtime. As an added benefit, SPX’s simple, economical single O-ring shaft seals provided an alternative to the more expensive and sensitive mechanical seals offered on the originally installed pumps.

The External Circumferential Piston (ECP) style rotors, with larger crossover clearances and higher efficiency, were able to stand up to the plant’s demanding performance requirements and eliminate their pump downtime. As an added benefit, SPX’s simple, economical single O-ring shaft seals provided an alternative to the more expensive and sensitive mechanical seals offered on the originally installed pumps.At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s

Why Having Critical Components on Hand Matters Manufacturing is a time-sensitive business where preventable equipment failures can cause production lines to stop running and lead

How Spiral and Booster Steam Ovens Are Transforming Food Processing Anderson Dahlen’s Spiral Steam Ovens and Booster Steam Ovens provide innovative cooking solutions to improve

Understanding the Difference: Fabrication vs. Machine Shops One of the most common questions from prospective customers is: “Are you a machine shop or a fabricator?”

Anderson Dahlen built an ultra-high vacuum chamber used for growing thin films, typically of refractory materials, using a high temp deposition process. Critical tolerances are

Meet our new Business Development Manager, AJ! AJ is from Moorhead, MN, and earned a B.S. in Mechanical Engineering from the University of North Dakota.

Anderson Dahlen

6850 Sunwood Drive NW

Ramsey, MN 55303

Phone: 763.852.4700

Fax: 763.852.4795

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.