Pipe Welding At Anderson Dahlen: Precision, Performance, And Proven Results

Why Pipe Welding Matters To Your Industry When your facility depends on piping to move liquids, air, gases, or steam, every weld becomes a point of trust. Pipe welding is

Why Pipe Welding Matters To Your Industry When your facility depends on piping to move liquids, air, gases, or steam, every weld becomes a point of trust. Pipe welding is

Anderson Dahlen supports the world’s most demanding industries with vacuum vessels that perform under the toughest conditions. We work closely with customers across a variety of market sectors: scientific instrumentation,

Meet Larry! Larry Forseth is a Fabricator II at Anderson Dahlen. With over 30 years of experience as a welder and fabricator, Larry brings exceptional skill and expertise to his

At Anderson Dahlen, safety isn’t just a box we check. It’s our number one core value: we put safety and qualify of life first. That’s why we’re proud to celebrate

Why Having Critical Components on Hand Matters Manufacturing is a time-sensitive business where preventable equipment failures can cause production lines to stop running and lead to rapid cost increases. Unexpected

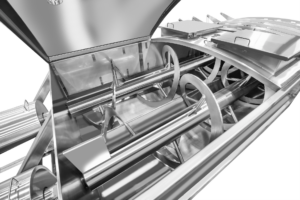

How Spiral and Booster Steam Ovens Are Transforming Food Processing Anderson Dahlen’s Spiral Steam Ovens and Booster Steam Ovens provide innovative cooking solutions to improve food processing while ensuring strict

Understanding the Difference: Fabrication vs. Machine Shops One of the most common questions from prospective customers is: “Are you a machine shop or a fabricator?” The truth is, Anderson Dahlen

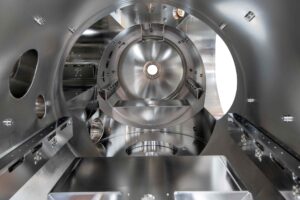

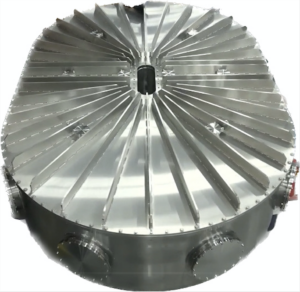

Anderson Dahlen built an ultra-high vacuum chamber used for growing thin films, typically of refractory materials, using a high temp deposition process. Critical tolerances are required for alignment of the

Meet our new Business Development Manager, AJ! AJ is from Moorhead, MN, and earned a B.S. in Mechanical Engineering from the University of North Dakota. He served eight years in

Meet Wyatt Craft, our new Business Development Manager! Wyatt received a Bachelor’s degree in Global Business from Saint John’s University and has three years of experience in Sales & Account

In this Q&A, Luke Stanley shares his story—from early days studying mechanical engineering to navigating a career shift during the pandemic and ultimately finding a home at Anderson Dahlen. Discover

Anderson Dahlen is excited to announce that our distribution segment has expanded to Chicagoland. Partnering with AD Process Equipment, a Gray company, our new stock room and inventory are in

The dairy industry encompasses an array of products, each with its own processing equipment requirements. Anderson Dahlen’s innovative approach gives us the unique ability to impact the market and focus

Discover how MIT and Commonwealth Fusion Systems are advancing fusion energy with high-temperature superconducting magnets, aiming for a sustainable and compact fusion power plant using one of Anderson Dahlen custom vacuum chambers.

Meet Matthew! Matthew Blaha is a Program Manager at Anderson Dahlen. He earned his Bachelor of Science degree from Minnesota State University, Mankato majoring in Automotive Engineering Technology with a

Increasing demand for smarter facilities and evolving customer needs are steering equipment manufacturers to incorporate more data into their equipment design and fabrication processes. This shift has led to increased

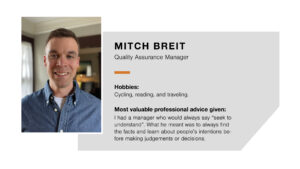

Meet Mitch! Mitch Breit is the Quality Assurance Manager at ADI. Mitch’s background consists of a Technical Diploma in Welding from Moraine Park Technical College, a Technical Diploma in Marine

If you found yourself here, you’re likely interested in welding as a career or wondering about the job outlook for welders. That’s great news, as welding jobs are on the

Last month, we shared top tips for enhancing process safety for industrial manufacturing organizations. We covered the advantages it poses for manufacturers, how to build an effective process safety program

Efficient material handling is a critical aspect of modern industrial operations. It ensures smooth movement and management of materials, ultimately leading to enhanced productivity and streamlined workflows. Over the years,

When it comes to industrial manufacturing, safety is the cornerstone of a successful operation. As we celebrate National Safety Month, it’s an opportune time to highlight the significance of process

In the realm of pharmaceutical manufacturing, maintaining a pristine and sterile environment is of utmost importance. Every aspect, from the equipment used to the manufacturing processes employed, must adhere to

Industrial automation in manufacturing has become more than just a buzzword – it’s now a crucial driver of efficiency, productivity and competitiveness in the market. With the rapid advancements in

The SPX Waukesha series of positive displacement pumps include advanced sanitation technologies, long-life features, and installation flexibility. They are also Clean-in-Place (CIP) capable that are engineered to perform in food

Our team is here to answer questions, provide quotes, and offer customer support. Let us know how we can help.